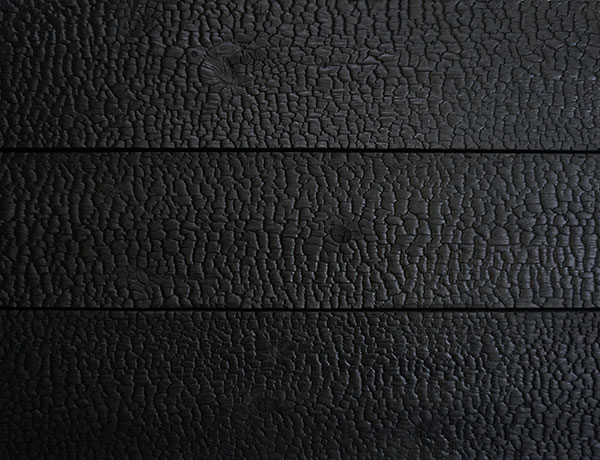

We produce our wood by charring it using the ancient Japanese technique known as Shou Sugi Ban, also called Yakisugi. This process creates a unique texture, protects the wood from harsh weather, and increases its lifespan.

We produce two types of burnt wood cladding:

For the finishing layer, we offer special sealers and oils to both enhance and protect the wood.

We provide shiplap, tongue and groove, and squared profiles.

Charred spruce is our most affordable product. The burnt timber is suitable for use in exteriors. We use high-quality Nordic spruce that is PEFC certified.

Charred larch is our most popular product with the best quality-price ratio. Burnt larch cladding is very durable and, therefore, it is perfectly suitable for exteriors.

Accoya is a premium choice; the charred layer is unique and beautiful. Charred Accoya has the best dimensional stability. There are no knots.

Charred Kebony Character is a premium wood known for its high quality and durability. The Kebony Character may contain knots and other natural characteristics.

Charred Kebony Clear is a premium choice. The charred layer is unique and beautiful. Charred Kebony has good dimensional stability. There are no knots.

At first, we char 2-3 mm of the timber cladding surface. Then, we brush the char away and coat it with special oil. Under the char layer, there is a strong surface with a unique texture.

Your country isn't listed? Contact us

Make an inquiryCharred timber cladding is weatherproof, and its surface does not change its colour over time. Also, the charred layer is resistant to mould, insects, water and even fire. In Japan, the Shou Sugi Ban technique for preserving wood was introduced hundreds of years ago.

The charred layer protects the timber, enhancing its durability and providing long-lasting protection. Charred wood can last for over 50 years, but in harsh weather conditions, the char layer may need reinforcement. With our expertise, we provide the best solutions to suit your needs, ensuring long-term performance and durability.

Charred wood offers a modern and sustainable solution for a wide range of design applications. Its unique appearance makes it perfect for both interior and exterior use. For exteriors, charred wood is often used in cladding, decking, and fencing, combining durability with a distinctive style.

Creating charred wood requires precision at every stage, from selecting the finest materials to carefully controlling the burning process. We prepare each piece with great care and precisely time the charring process to ensure consistent and high-quality results.

We produce charred timber cladding using the traditional Shou Sugi Ban method, avoiding the use of gas or fuels for charring – gas is used to ignite the fire. Our advanced technology allows the wood to burn on its own, reducing waste and conserving natural resources, ensuring a climate-friendly approach to creating outstanding timber products.

In collaboration with Tallinn University of Technology (TalTech), we have extensively tested our products to validate the long-term durability of the charred wood. Our research also focused on identifying the best finishing options to preserve the carbonised surface, ensuring it maintains its integrity over time.

Our commitment to sustainability and responsible forestry practices ensures that our products are sourced from forests that meet strict environmental, social, and economic standards, protecting biodiversity and supporting local communities.

We hold the following certificates and memberships: